Supply Challenges to Persist, Be Patient and Proactive

Just-in-time logistics and supply planning has turned into ‘just hopefully sometime this year’ as the wine industry remains embroiled in the ongoing global supply chain disruptions.

The delays, price increases and lack of supplies is expected to persist through 2022 and possibly even into next year causing experts at the recent Unified Wine & Grape Symposium in Sacramento, Calif., to urge patience, long-term planning and diversifying one’s sources of supply to navigate the ongoing disruptions.

The Unified conference featured panels on supply chain management and risk management, which have both been key concerns since the onset of the global pandemic in March 2020. In an example of those challenges, several of the panelists had to participate via teleconference because of the recent surge of COVID-19 that prevented many attendees, speakers and exhibitors from traveling to the show that was held in person.

If there is one bright side it’s that because the supply challenges are so widespread and in some cases have gone viral — such as the Ever Given getting lodged in the Suez Canal and the Christmas cream cheese shortage — that consumers are likely more tolerant of price increases than at any other given time in recent history.

But even if wineries can raise prices to offset cost increases, the challenges of just getting business done remain significant. Turrentine Brokerage partner Marc Cuneo, who moderated the session on the global supply chain, said logistics and supply now dominate the company’s conversations with clients. “In the last two years it comes up in every client conversation,” he said. “It’s almost as big, if not bigger, than where we are in the cycle of wine and grapes.”

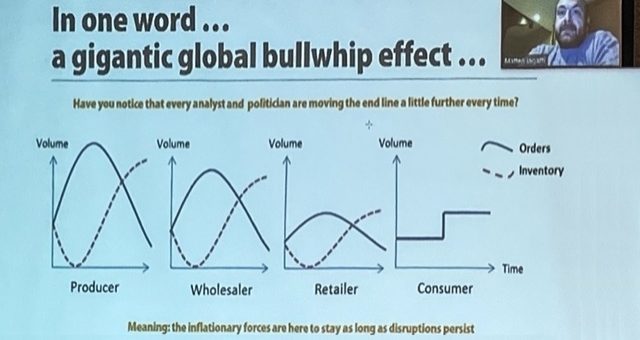

Matteo Iagatti, a senior specialist on food and agriculture supply chains with Rabobank Utrecht, joined the session remotely and described how COVID and significant swings in consumer demand, especially for durable goods in 2020, trigged a global “bullwhip” effect that remains in play. He advised finding local sources of supply, regular negotiations with one’s supplier, transferring costs through price when possible, cooperative supply purchasing and planning for the long term to get through the disruptions for the rest of the year.

Jackson Family Wines’ Senior Vice President of Supply Chain Mike Eaton said over the past two decades the supply sector has been driven by outsourcing, cost cutting and an incessant focus on efficiency and lean operations. “Everyone was running really, really lean and when you run lean it requires a great deal of coordination and cooperation,” he said of tglobal logistics. “We extended ourselves to where we were open to risk everywhere.”

Consolidation among suppliers and a reliance on oversees manufacturers and distributors also contributed to the current challenges, which is why Eaton and other speakers stressed the importance of finding local suppliers.

At the winery, Eaton has implored his team to think how they can simplify what they need from suppliers but also make themselves a better client such as collaborating on longer lead times to limit surprises and seeing what else they can do to flatten the demand curve.

Earlier investments in planning, such as building a team of supply experts, are also paying huge dividends today. “Really smart people in planning are worth their weight in gold,” he said. “That’s something I heavily invested in, building a department over the past five years, and I can’t tell you how valuable they were through the pandemic.”

Alison Crowe is the director of winemaking at Plata Wine Partners, which produces more than 400,000 cases a year primarily for private label programs. Crowe stressed building a culture of resiliency among one’s employees and in operations will go a long way toward handling disruptions.

Speaking to the Unified audience from Plata’s facility in Napa, Calif., Crowe said Plata transitioned to only using domestic glass about three years ago which proved a prescient move and continues to seek local sources for key materials. She works with multiple bottling and packaging facilities and can bottle as needed depending on the availability of supplies such as labels. Ordering those materials earlier and having them on hand in a warehouse is another major advantage.

She said better long-term demand planning helps ensure fewer supply headaches and added different winemaking practices can help as well. New products for cold stabilizing wines have helped her tighten up her bottling schedules by reducing the overall time needed for stability treatments while giving her greater precision on when wines will be ready for blending and bottling.

Having teams in place who can manage and maximize that efficiency also comes from a resilient company culture, she said.

And Eaton said one’s employees can also be the source of effective innovation. He said a young bottling line technician had the idea to get around delays from waiting on replacement parts from Europe by buying a 3D printer and simply printing them himself. The first parts lasted a shift, improvements helped them last an entire week and Eaton said they can now run lines for nearly a month on printed parts that cost next to nothing and are available as needed.

Article from winebusiness.com Written by Andrew Adams

- Posted by activ8commerce

- On February 2, 2022

- 0 Comment